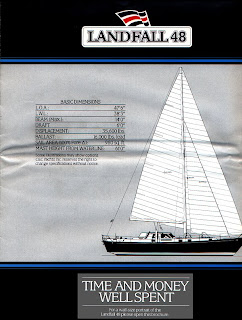

So we bought this boat knowing full well that the engine didn't work. It had sat secure to the dock for just over two years with no heat or fans in it and all the hatches and windows leak (you get the picture). My surveyor said it was the top of the list (not the list you want to be on). The yard nic named it the LANDFILL 48 when I saw it I new it could be a great boat again. I took Karen down to it knowing full well that if I could get her on my side (she always seems to come around) all would be right. First was to throw out anything not attached. If it had fabric or foam in it,out it goes.

We spent about 20 hours cleaning throwing away and finding out what was what. The batteries were all dry so nothing 12v worked shore power was working so we replaced 6 golfcart batteries and some stuff started to work. The lighting was the first change raplacing the main cabin lights so we could see. Than into the engine room. Right from the start we knew the engine was coming out and a new one going in. Everything was being disconnected Engine out new Yanmar 100hp in .How tough can that be.